Coker Complex

Consortuim (Petrojet & Enppi) in developing & upgrading of Coker complex including Engineering, Procurement and Construction works

Developing phenol unit extraction to be replaced by N.M.B for saving environment, and increasing production capacity to 283 KT/year

Suez

Suez Oil Processing Co.

Consortuim (Petrojet & Enppi) in developing & upgrading of Coker complex including Engineering, Procurement and Construction works

Alexandria, Egypt

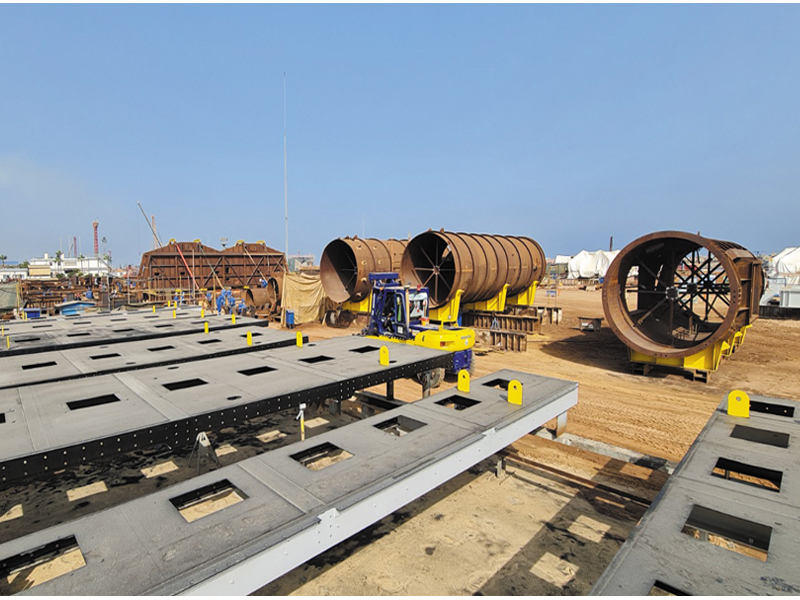

ELAB

Development of a Linear Alkyl Benzene Plant in Alexandria, North of Egypt with a production capacity of 100,000 Tons/Year. Plant consists of Process Unit–Utilities – Storage Facilities – Service Buildings. EPC Contract is performed by Consortium of (PETROJET – ENPPI – GS), where Engineering & Procurement are performed by ENPPI & GS while PETROJET scope is the Construction and Fabrication works.

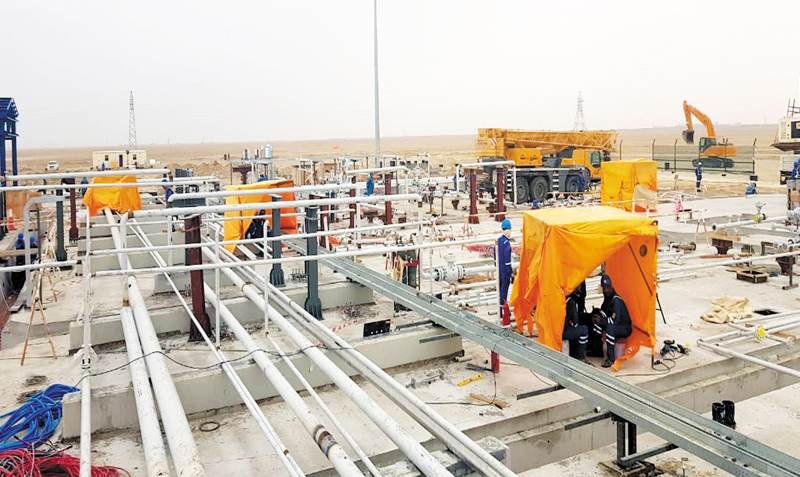

Rumaitha/Shanayel area

Abu Dhabi Company for Onshore Petroleum Operations

Part 1 : Rumaitha/Shanayel Production Restoration Rumaitha/Shanayel restoration consists of (14 wells) to compensate production from high GOR wells (6 OP and 8 WAG). All producer wells are expected to be provided with gas lift. It includes two “Ra/Sn Phase III Batch 2” wells brought forward to year 2018 (Ra-122 oil producer and Ra-123 WAG injector). Part 2 : Rumaitha Technical Rate Rumaitha Phase I/II production requires sustaining its 20% technical rate. This requires drilling six (6) oil producers and six (6) WAG injectors, Two oil producers out of the six are “Ra/Sn Phase III Batch 2” wells brought forward and two WAG injectors out of the six injectors are “Ra/Sn Phase III Batch 2” wells which are brought forward. The Batch 2 wells are located in Cluster Y. Production from clusters GG and FF will be routed to CPP phase I/II.