E-METHANEX METHANOL PLANT

construction of Methanol plant to produce of 1.3 million ton per year in Damietta on the Mediterranean Sea in Egypt.

The target of the project is to increase the productivity of El Salam gas station to 410 MMCFD by doubling the processing units to 4 units then transporting the processed gas by el Obayed /el Amerya pipeline

Damietta, Egypt

Techint - (Egyptian Methanex Methanol Company)

construction of Methanol plant to produce of 1.3 million ton per year in Damietta on the Mediterranean Sea in Egypt.

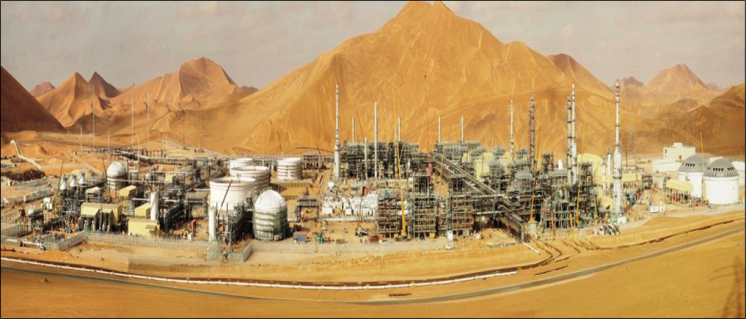

Algeria

Groupement Berkine (JV of Sonatrach and Anadarko)

The El Merk Project aims at establishing the surface facilities required for the exploitation of hydrocarbon liquid reserves of six reservoirs in Blocks 208, 405a and 212 in Algeria. The project comprises building a 98,000 bpd central processing facility including a 29,000 bpd condensate unit, a 31,000 bpd LPG unit and a 600 MMCFD NGL train Constructed of a 500 MMCF Of residue and re-injection gas compression and approximately 80,000 bpd of produced water treatment and re-injection facilities.

yanbu- Saudi Arabia

Aramco- Techint

Execution of civil and mechanical works solid handling package including conveyor belt, storage buildings, underground piping, piping, pipeline, steel structure, equipment erection, insulation and painting works.