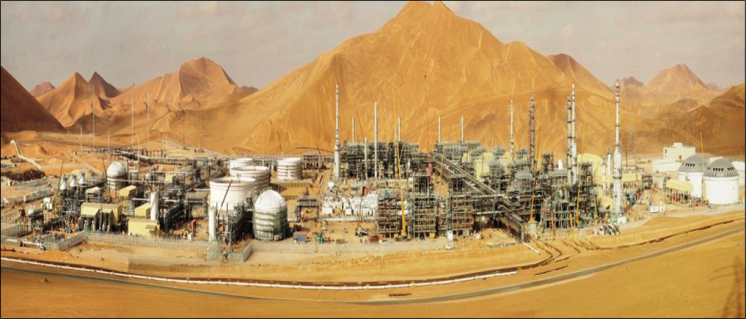

Luberef Growth II project

Package I Revamp existing vacuum ditllation unit (40,000bpsd to 65,000bpsd) Upgrade existing HCU (23,000bpsd to 34,500bpsd) Upgrade existing IDW (18,217bpsd to 29,147bpsd) Utilities: Upgrade existing utilities to meet the revamp requirements of ISBL Process support until upgrade (SRU, HRU, ARU & SWS) Pacakge II Product Distribution System: install & upgrade the product distribution system (Tanks, Pipelines & Loading Arms) to meet the revamp requirements Utilities: Upgrade existing utilities to meet the revamp requirements of OSBL