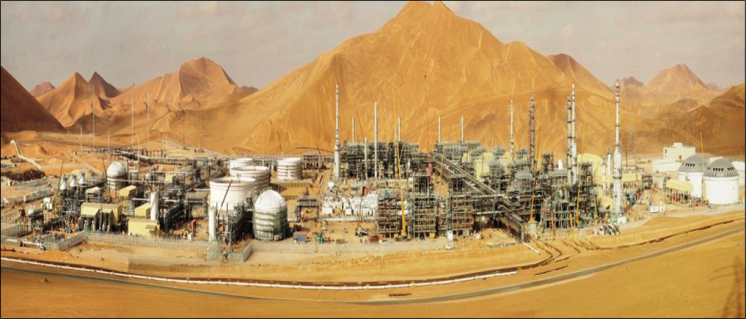

ASORC Naphtha Complex Utilities & Offsite

Petrojet scope of work includes all Civil & Mechanical Works of both the UTILITIES/OFFSITE and ISBL, including procurement, design, fabrication, inspection, construction, installation, erection, testing, pre-commissioning activities and assistance during commissioning and start up