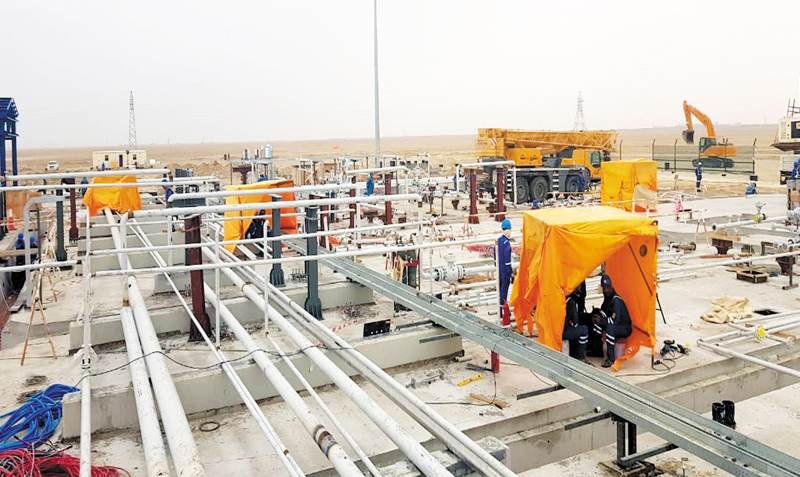

ASSIL & KARAM GAS DEVELOPMENT

Project aims at increasing the gas production at BED-3 up to 200 MMSCFD by bringing gas from newly discovered wells at Karam (5 Wells) and Assil (2 Wells) . Development includes a new CO2 Removal Plant (CRP) to remove high CO2 content prior to further processing the gas at the existing BED-3 facilities to meet the export CO2 specifications